| Home page About us Products Contact us Site map E-mail us for Inquiry |

|

|

| You are here >> Home page >> Products >> PCD cutting tool blanks |

|

|||||

|

|

||||

PCD cutting tool blank |

||||

Advantages of PCD cutting tool blanks: 1. Long working life. 2. Uniform surface finish. 3. Reduces machine down time. 4. Highly improved workpiece quality and excellent dimensional control. 5. Increase productivity. 6. High material removal rate. 7. Lower cost per piece. 8. The working life of a PCD cutting edge is usually 50 to 250 times longer than that of traditional sintered carbide cutting tools. |

PCD Cutting Tool Blanks Application Recommendation |

|||

Grades |

Characters |

Applications |

Advantages |

W5 fine grain size |

1.Average grain size:5μm 2.High diamond content over90% 3.Laser cutting or wire EDM cutting |

Aluminum,Brass/Copper,Precious metals,Wood composites,Plastic | Excellent surface finish |

W10 medium grain size |

1.Average grain size:10μm 2.High diamond content over90% 3.Laser cutting or wire EDM cutting |

<14% Si/Al alloys,Copper alloys,Graphite and graphite composites,Green ceramics and carbides | Excellent resistance,good surface finish |

W25 coarse grain size |

1.Average grain size:25μm 2.High diamond contentover90% 3.Laser cutting or wire EDM cutting |

>14% Si/Al alloys,metal matrix composites,Bi-metals(aluminum/castiron),sintered ceramics and carbides | Long life,extremely high wear resistance |

| CBN cutting tool blanks characteristics: 1. welded CBN layer and tungsten carbide substrate. 2. High abrasion resistance. 3. High fracture resistance. 4. Good chemic stability. 5. High precision on processing tool parts. 6. Good consistency of processing. |

CBN cutting tool blanks application: 1. Turning of cast iron. 2. metal powders. 3. exotic materials and heat resistant alloys. 4. High speed milling of gray cast iron. |

CBN Cutting Tool Blanks Application Recommendation |

|||

Item number |

Main Bond |

Structural Characteristics |

Application |

CBN90 |

Titanium nitride |

Large particles,higher wear resistence, good high-speed continuous cutting performance. |

Used for cutting the iron group materials, and the cutting rate is from medium to high |

CBN80 |

Cobalt, wolfram |

It’s the versatile material, suitable for processing various types of materials |

Gray cast iron, chilled cast iron, cast iron nickel |

CBN70 |

Nitrogen and carbon Titanium, Aluminium Oxide |

Has excellent impact resistance and chemical stability. |

Suitable for processing hardened steel with high hardness, both continuous and intermittent process |

CBN60 |

Titanium carbon |

High wear resistance and high impact resistance. |

High-speed continuous process hardened steel |

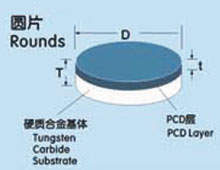

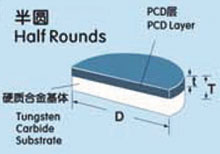

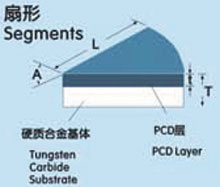

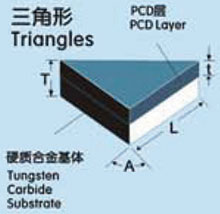

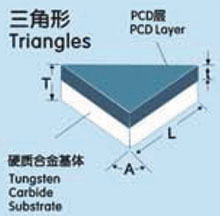

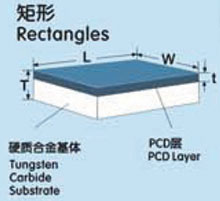

Shape |

Item Number |

Dimension (mm) |

||

Angle (A) |

Diameter (D) |

Thickness (T) |

||

|

R360/8.0 |

360 |

8.0 |

1.6 / 2.0 / 3.2 |

R360/13.2 |

360 |

13.2 |

1.6 / 2.0 / 3.2 |

|

R360/30.0 |

360 |

30.0 |

1.6 / 2.0 / 3.2 |

|

R360/38.0 |

360 |

38.0 |

1.6 / 2.0 / 3.2 |

|

R360/44.0 |

360 |

44.0 |

1.6 / 2.0 / 3.2 |

|

|

R180/8.0 |

180 |

8.0 |

1.6 / 2.0 / 3.2 |

R180/13.2 |

180 |

13.2 |

1.6 / 2.0 / 3.2 |

|

R180/30.0 |

180 |

30.0 |

1.6 / 2.0 / 3.2 |

|

R180/38.0 |

180 |

38.0 |

1.6 / 2.0 / 3.2 |

|

R180/44.0 |

180 |

44.0 |

1.6 / 2.0 / 3.2 |

|

R45/3.8 |

45 |

3.8 |

1.6 / 2.0 / 3.2 |

R45/4.5 |

45 |

4.5 |

1.6 / 2.0 / 3.2 |

|

R45/6.3 |

45 |

6.3 |

1.6 / 2.0 / 3.2 |

|

R60/3.8 |

60 |

3.8 |

1.6 / 2.0 / 3.2 |

|

R60/4.5 |

60 |

4.5 |

1.6 / 2.0 / 3.2 |

|

R60/6.4 |

60 |

6.4 |

1.6 / 2.0 / 3.2 |

|

R90/3.9 |

90 |

3.9 |

1.6 / 2.0 / 3.2 |

|

R90/4.6 |

90 |

4.6 |

1.6 / 2.0 / 3.2 |

|

R90/6.5 |

90 |

6.5 |

1.6 / 2.0 / 3.2 |

|

T35/3.8 |

35 |

3.8 |

1.6 / 2.0 / 3.2 |

T35/4.5 |

35 |

4.5 |

1.6 / 2.0 / 3.2 |

|

T35/5.0 |

35 |

5.0 |

1.6 / 2.0 / 3.2 |

|

T35/7.0 |

35 |

7.0 |

1.6 / 2.0 / 3.2 |

|

T35/9.0 |

35 |

9.0 |

1.6 / 2.0 / 3.2 |

|

T45/4.0 |

45 |

4.0 |

1.6 / 2.0 / 3.2 |

|

T45/5.0 |

45 |

5.0 |

1.6 / 2.0 / 3.2 |

|

T45/6.2 |

45 |

6.2 |

1.6 / 2.0 / 3.2 |

|

T55/4.0 |

55 |

4.0 |

1.6 / 2.0 / 3.2 |

|

T55/5.0 |

55 |

5.0 |

1.6 / 2.0 / 3.2 |

|

T55/7.0 |

55 |

7.0 |

1.6 / 2.0 / 3.2 |

|

T60/3.0 |

60 |

3.0 |

1.6 / 2.0 / 3.2 |

|

T60/4.0 |

60 |

4.0 |

1.6 / 2.0 / 3.2 |

|

T60/5.0 |

60 |

5.0 |

1.6 / 2.0 / 3.2 |

|

T60/6.5 |

60 |

6.5 |

1.6 / 2.0 / 3.2 |

T60/7.0 |

60 |

7.0 |

1.6 / 2.0 / 3.2 |

|

T60/9.5 |

60 |

9.5 |

1.6 / 2.0 / 3.2 |

|

T90/3.0 |

90 |

3.0 |

1.6 / 2.0 / 3.2 |

|

T90/4.0 |

90 |

4.0 |

1.6 / 2.0 / 3.2 |

|

T90/5.0 |

90 |

5.0 |

1.6 / 2.0 / 3.2 |

|

T90/6.5 |

90 |

6.5 |

1.6 / 2.0 / 3.2 |

|

T90/7.5 |

90 |

7.5 |

1.6 / 2.0 / 3.2 |

|

T90/9.5 |

90 |

9.5 |

1.6 / 2.0 / 3.2 |

|

L3.5/3.0 |

3.5 |

3.0 |

1.6 / 2.0 / 3.2 |

L4.0/2.5 |

4.0 |

2.5 |

1.6 / 2.0 / 3.2 |

|

L5.0/2.0 |

5.0 |

2.0 |

1.6 / 2.0 / 3.2 |

|

L5.0/2.5 |

5.0 |

2.5 |

1.6 / 2.0 / 3.2 |

|

L5.0/3.5 |

5.0 |

3.5 |

1.6 / 2.0 / 3.2 |

|

L5.0/4.0 |

5.0 |

4.0 |

1.6 / 2.0 / 3.2 |

|

L6.0/3.5 |

6.0 |

3.5 |

1.6 / 2.0 / 3.2 |

|

L6.0/4.3 |

6.0 |

4.3 |

1.6 / 2.0 / 3.2 |

|

L6.0/4.5 |

6.0 |

4.5 |

1.6 / 2.0 / 3.2 |

|

L6.0/5.0 |

6.0 |

5.0 |

1.6 / 2.0 / 3.2 |

|

L7.0/3.0 |

7.0 |

3.0 |

1.6 / 2.0 / 3.2 |

|

L10/3.0 |

10 |

3.0 |

1.6 / 2.0 / 3.2 |

|

L11/2.5 |

11 |

2.5 |

1.6 / 2.0 / 3.2 |

|

L12/3.0 |

12 |

3.0 |

1.6 / 2.0 / 3.2 |

|

L13/3.0 |

13 |

3.0 |

1.6 / 2.0 / 3.2 |

|

L20/20.0 |

20 |

20 |

1.6 / 2.0 / 3.2 |

|

L25/3.0 |

25 |

3.0 |

1.6 / 2.0 / 3.2 |

| Tel: 0086-731-89853480 Mobile&WhatsApp:+86 13875858570 |

E-mail for inquiry: sales@china-superabrasives.com |