| Home page About us Products Contact us Site map E-mail |

|

|

| You are here >> Home page >> Products >> PCD inserts |

| PCD inserts |

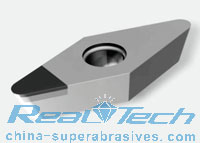

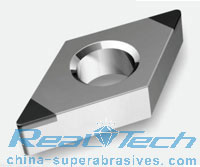

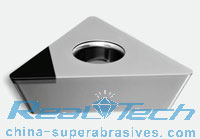

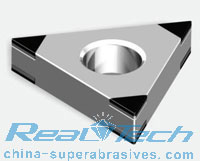

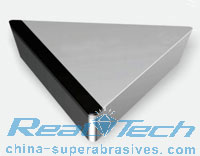

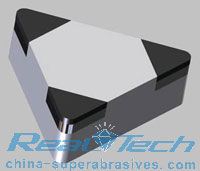

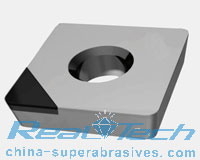

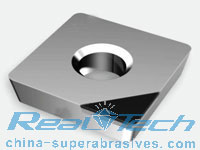

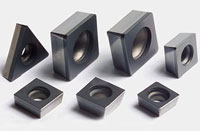

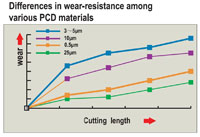

Welcome you visit our new website for CBN and PCD Inserts: www.cbncut.com We supply premium quality PCD inserts with long cutting service life and high speed, inserts can be sintered from one to four edges for different cutting usage, These sintered PCD insert materials have a variety of uses,most notably for cutting tools machining non-ferrous metals and non-metallic materials and for wear parts. An advantage of these materials is that their structure and composition can be engineered to haveproperties tailored to specific applications and operations. As a cutting tool material,PCD insert is generally recommended for the machining of non ferrous work-piece materials where high abrasion resistance is required. Examples of typical work piece materials are as follows: metal matrix composite,silicon aluminum alloys,copper,ceramics,fiber glass,carbon fiber reinforced plastics,rubber,pre-sintered and sintered tungsten carbide. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PCD inserts |

PCD inserts |

|

|

|||

|

|

|

|

|

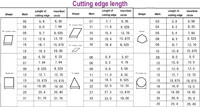

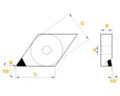

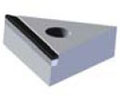

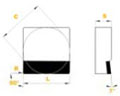

PCD insert shape |

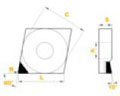

PCD insert graph |

Type |

Dimension (mm) |

PCD insert shape |

PCD insert graph |

Type |

Dimension (mm) |

||||||||

L |

C |

s |

d |

R |

L |

C |

s |

d |

R |

||||||

|

|

110302 |

11.1 |

6.35 |

3.18 |

2.8 |

0.2 |

|

|

160402 |

16.6 |

9.525 |

4.76 |

3.81 |

0.2 |

110304 |

11.1 |

6.35 |

3.18 |

2.8 |

0.4 |

160404 |

16.6 |

9.525 |

4.76 |

3.81 |

0.4 |

||||

110308 |

11.1 |

6.35 |

3.18 |

2.8 |

0.8 |

160408 |

16.6 |

9.525 |

4.76 |

3.81 |

0.8 |

||||

160404 |

16.6 |

9.525 |

4.76 |

4.4 |

0.4 |

160412 |

16.6 |

9.525 |

4.76 |

3.81 |

1.2 |

||||

160408 |

16.6 |

9.525 |

4.76 |

4.4 |

0.8 |

||||||||||

160412 |

16.6 |

9.525 |

4.76 |

4.4 |

1.2 |

|

|

070202 |

7.7 |

6.35 |

2.38 |

2.8 |

0.2 |

|

|

150404 |

15.5 |

12.7 |

4.76 |

5.16 |

0.4 |

070204 |

7.7 |

6.35 |

2.38 |

2.8 |

0.4 |

150408 |

15.5 |

12.7 |

4.76 |

5.16 |

0.8 |

||||

070208 |

7.7 |

6.35 |

2.38 |

2.8 |

0.8 |

150412 |

15.5 |

12.7 |

4.76 |

5.16 |

1.2 |

||||

11T302 |

11.6 |

9.525 |

3.97 |

4.4 |

0.2 |

||||||||||

11T304 |

11.6 |

9.525 |

3.97 |

4.4 |

0.4 |

||||||||||

11T308 |

11.6 |

9.525 |

3.97 |

4.4 |

0.8 |

|

|

160404 |

16.5 |

9.525 |

4.76 |

3.81 |

0.4 |

|

|

120404 |

12.9 |

12.7 |

4.76 |

5.16 |

0.4 |

160408 |

16.5 |

9.525 |

4.76 |

3.81 |

0.8 |

120408 |

12.9 |

12.7 |

4.76 |

5.16 |

0.8 |

||||

160412 |

16.5 |

9.525 |

4.76 |

3.81 |

1.2 |

120412 |

12.9 |

12.7 |

4.76 |

5.16 |

1.2 |

||||

|

|

060202 |

6.4 |

6.35 |

2.38 |

2.8 |

0.2 |

|

|

080404 |

8.7 |

12.7 |

4.76 |

5.16 |

0.4 |

060204 |

6.4 |

6.35 |

2.38 |

2.8 |

0.4 |

080408 |

8.7 |

12.7 |

4.76 |

5.16 |

0.8 |

||||

060208 |

6.4 |

6.35 |

2.38 |

2.8 |

0.8 |

080412 |

8.7 |

12.7 |

4.76 |

5.16 |

1.2 |

||||

09T302 |

9.7 |

9.525 |

3.97 |

4.4 |

0.2 |

||||||||||

09T304 |

9.7 |

9.525 |

3.97 |

4.4 |

0.4 |

||||||||||

09T308 |

9.7 |

9.525 |

3.97 |

4.4 |

0.8 |

|

|

060202 |

6.35 |

6.35 |

2.38 |

2.8 |

0.2 |

|

|

060204 |

6.35 |

6.35 |

2.38 |

2.8 |

0.4 |

060204 |

6.35 |

6.35 |

2.38 |

2.8 |

0.4 |

070202 |

7.94 |

7.94 |

2.38 |

3.4 |

0.2 |

||||

060208 |

6.35 |

6.35 |

2.38 |

2.8 |

0.8 |

09T301 |

9.525 |

9.525 |

3.97 |

4.4 |

0.1 |

||||

070202 |

7.94 |

7.94 |

2.38 |

3.4 |

0.2 |

09T302 |

9.525 |

9.525 |

3.97 |

4.4 |

0.2 |

||||

070204 |

7.94 |

7.94 |

2.38 |

3.4 |

0.4 |

09T304 |

9.525 |

9.525 |

3.97 |

4.4 |

0.4 |

||||

070208 |

7.94 |

7.94 |

2.38 |

3.4 |

0.8 |

||||||||||

09T302 |

9.525 |

9.525 |

3.97 |

4.4 |

0.2 |

||||||||||

09T304 |

9.525 |

9.525 |

3.97 |

4.4 |

0.4 |

||||||||||

09T308 |

9.525 |

9.525 |

3.97 |

4.4 |

0.8 |

|

|

090302 |

9.525 |

9.525 |

3.18 |

X |

0.2 |

|

|

090302 |

9.525 |

9.525 |

3.18 |

X |

0.2 |

090304 |

9.525 |

9.525 |

3.18 |

X |

0.4 |

090304 |

9.525 |

9.525 |

3.18 |

X |

0.4 |

||||

090308 |

9.525 |

9.525 |

3.18 |

X |

0.8 |

090308 |

9.525 |

9.525 |

3.18 |

X |

0.8 |

||||

120304 |

12.7 |

12.7 |

3.18 |

X |

0.4 |

120304 |

12.7 |

12.7 |

3.18 |

X |

0.4 |

||||

120308 |

12.7 |

12.7 |

3.18 |

X |

0.8 |

120308 |

12.7 |

12.7 |

3.18 |

X |

0.8 |

||||

120312 |

12.7 |

12.7 |

3.18 |

X |

1.2 |

120312 |

12.7 |

12.7 |

3.18 |

X |

1.2 |

| Tel: 0086-731-89853480 Fax: 0086-731-89853490 Mobile: 0086-13875858570 |

E-mail: sales@china-superabrasives.com |